At American Industrial Company, we are equipped to handle large, complex jobs with expediency.

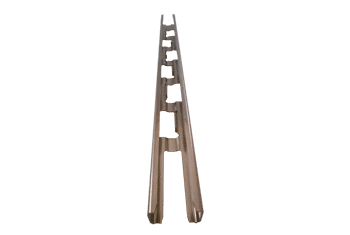

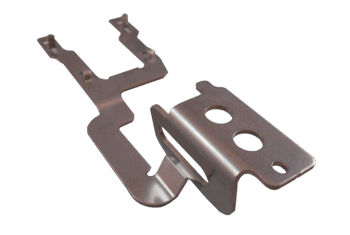

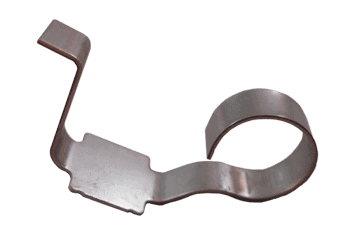

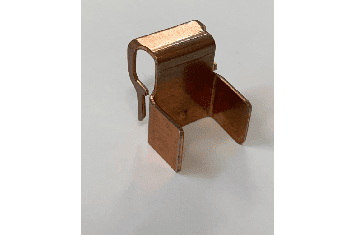

Our Stainless Steel Portfolios display our expertise in all forms of stamping, including forming, bending, progressive, blanking, coining, piercing, and shallow draw. By working with metals such as cold/hot rolled and galvanized steels, aluminum, brass and copper, and stainless, we are capable of stamping products with thicknesses ranging from 0.005” to 0.188” and to tolerances of ±0.001”.