American Industrial Company (AIC) is a world class manufacturer of high-quality and precise carbon steel metal stampings. Founded in 1981, we have been an industry leader specializing in complete turnkey packages, providing our expertise every step of every fabrication project.

Contact us here for specific questions >>

Precision carbon steel metal stampings are at the core of the services AIC offers. Our stamping capabilities include progressive, forming, bending, blanking, coining, forming, secondary, shallow draw, and piercing. Our processes allow us to stamp products with thicknesses of 0.005” to 0.188” and to tolerances of ±0.001”.

AIC are also experts in stamping parts in High Strength Low Alloy (HSLA) steel, which allows us to produce high quality parts utilizing load tonnage monitors, proximity sensors, infrared lasers, fiber optics, and other devices to ensure accuracy.

AIC’s broad range of capabilities makes us the first choice of fabricator across industries. Our sample portfolio includes such diverse projects as:

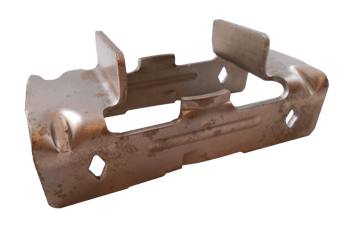

Chromate Plated Custom Bracket for the Auto Industry

This prototyping project was commissioned by a customer in the automotive industry. AIC produced twelve brackets for us in safely securing floor mats. In order to accurately create the profile on a press brake, we designed and built soft tooling from cold rolled steel, spot-welded the components, and applied a clear zinc chromate plating to protect the brackets from rust and corrosion. The brackets were completed to measure 1.25” in length and 2.0” in width upon completion, and were produced within a ±0.10” tolerance requirement. These prototypes were critical for order approval, with our clients’ engineering, design, and material specifications met and shipped to the customer within a three-week timeframe.

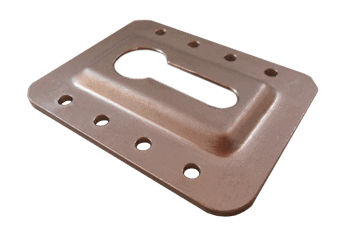

Progressive Die Stamped Wear Plate for the Construction Industry

This project involved a designing a progressive die stamped wear plate for a manufacturer in the construction industry. The final product required AIC to adhere to the right combination of strength, hardness, and toughness requirements. Our qualified team of engineers was able to develop a progressive die stamping process which allowed us to create this geometrically complex part with tight tolerance bends, angles, channels, and radii. Within a mere two weeks, AIC was able to cold roll tempered steel, apply a ferritic nitrocarburizing treatment, and perform quality control and ship 150,000 units of this critical component.

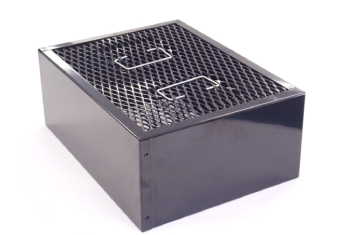

Metal Stamped Base Assembly for the Power Tool Industry

This project was prototyped for a power tool manufacturer. Our well-equipped facility and team of experts allowed us to use a variety of fabrication processes to create the pin, channel, base, rear nose, and latch components. The project involved not only our design engineering capabilities, but our stamping, milling, and casting processes as well. Through the course of this project, our welding technicians were able to showcase their skills in TIG and brazing during the assembly process. Furthermore, our technicians were able to complete all components of the plan to assemble and ship 2,500 units in only three months.

Find out much more about our metal stamping capabilities from our individual case studies. Let us know today how we can help you fill your next carbon steel stamping requirements.