At American Industrial, we are well established as a premier source of precision metal stamping and die cutting services. Since our establishment in 1981, we have been providing a comprehensive set of manufacturing services that are based on a culture of quality.

We operate a facility and quality program that is ISO 9001:2008 certified. Our Chicago facility is conveniently located in close proximity to O’Hare Airport. This added logistical advantage lets us respond to your needs quickly and effectively, and adds further value to our wide range of capabilities.

One of our specialties is servicing customers in the automotive industry. This vast industrial vertical demands quality, precision, and on-time delivery. Our reputation for upholding these critical capacities is what brought them to us for this project.

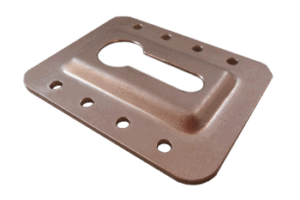

The bracket pictured here is designed to safely secure the floor mat in an automotive application. This project required that we produce twelve of the brackets for a high visibility prototyping project. The bracket was composed of cold rolled steel (CRS) and formed using cold tooling, which was the optimal solution to satisfy the needs of a prototype project.

We accurately created the profile on a press brake, and then utilized spot welding for assembly; this process imparted all the strength necessary without the cost of other methods. After a comprehensive quality check, the component’s brackets were subject to a zinc and clear chromate plating to inhibit rust and corrosion.

Once completed, these prototype brackets measured 1.25” in length and 2.0” in width, and all of them were fabricated within the ±0.010” tolerance requirement. These pre-production samples were critical for order approval. As a first article, meeting spec is critical; however, with our advanced quality program, the same accuracy can be met whether it’s five parts, such as this project, or 5 million.

In each case, documentation outlining the physical and functional inspection processes can be provided to validate that we met the engineering, design, and material specifications before shipping to the customer. For this project, all of this was completed within the three-week delivery timeline.

To learn more about this project, or how we can be your prototyping partner, contact us today.