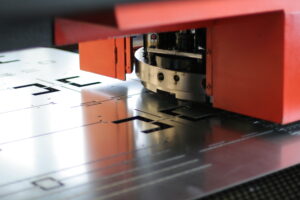

Stamped metal components form the building blocks of vehicles, equipment, electronics, appliances, tools, and so much more. Precision metal stamping processes employ a wide range of specialty equipment to cut, pierce, bend, and form sheet metal to meet modern needs. Steel and steel alloys, brass, aluminum, and copper are all popular materials for stamping projects,…

A Closer Look: How Metal Stampings Work

Metal stamping is used across a huge range of industries. Original equipment manufacturers (OEMs) typically utilize metal stamping to produce parts in situations in which casting would be too expensive. Metal stamping is much more cost-efficient, as sheet metal is easily recyclable. OEMs, especially those in the automotive, appliance, and aerospace industries, often drive the…