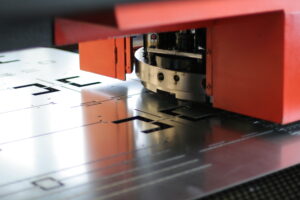

Progressive stamping is an accurate and cost-effective method for automated metal forming that can achieve high production volumes without compromising product quality. By incorporating several steps into one metal forming process, progressive die stamping allows manufacturers to produce complex goods using the best metals for stamping without straining the substrate or interrupting production. Based on…

Ferrous & Non-Ferrous Metal Stampings

Both ferrous and non-ferrous metals are suitable for precision metal stamping, each bringing unique advantages to their end-use applications. American Industrial Company (AIC) is an industry-leading fabricator of precision, high-quality non-ferrous metal stampings with over 30 years of experience. With expertise in a wide range of industries, AIC can help you with all your stamping…

Metal Stamped Parts for the Military and Defense Industries

Defense and aviation equipment – from equipment trailers to aviation equipment to armored ground support vehicles – rely heavily on metal stamped components. Metal stamped parts are crafted from sheet metal, which is formed into a predefined shape by highly specialized metal stamping machinery and supporting software. In the production of essential components, like aviation gauges…

Why Metal-Stamped Components are crucial for the Aerospace Industry

Commercial aviation manufacturers continually strive to improve their vehicles’ fuel economy and passenger comfort. Additionally, aerospace OEMs must adhere to stringent safety guidelines as specified by governments and industry groups. These competing pressures mean that aviation components must be designed to the tightest tolerances possible. At every step of the process, from concept to tooling…

Key Benefits of Working with a U.S. Manufacturer

The old saying “you get what you pay for” still holds true today––particularly when it comes to manufacturing. For those looking to get the best value for their money in a manufactured product, you should look no further than your own backyard. While the allure of cheaper products may be drawing many companies to look…

Metal Stamping Expected to Grow in 2018

Metal stamping is set to have a great year in 2018—even beyond the already impressive year the sector experienced in 2017. This growth in precision metal stamping may largely be attributed to growth in the U.S. economy, which is set to experience an additional 2% GDP growth this year. Across the United States, new markets…

Five Industries That Rely Upon Custom Metal Stamping

Stamped metal components form the building blocks of vehicles, equipment, electronics, appliances, tools, and so much more. Precision metal stamping processes employ a wide range of specialty equipment to cut, pierce, bend, and form sheet metal to meet modern needs. Steel and steel alloys, brass, aluminum, and copper are all popular materials for stamping projects,…

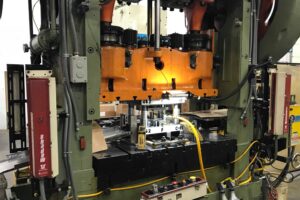

A Closer Look: How Metal Stampings Work

Metal stamping is used across a huge range of industries. Original equipment manufacturers (OEMs) typically utilize metal stamping to produce parts in situations in which casting would be too expensive. Metal stamping is much more cost-efficient, as sheet metal is easily recyclable. OEMs, especially those in the automotive, appliance, and aerospace industries, often drive the…

Metal Stamping Quality Control

When selecting metal formed parts, it’s critical to partner with a reliable, knowledgeable manufacturer who employs comprehensive quality assurance processes. This will help ensure you receive the highest-quality metal formed parts available, without the need for frequent maintenance or costly downtime. At American Industrial Corporation (AIC), we aim to provide industry-leading quality assurance throughout every…

How Metal Stamping Can Impact Your Bottom Line

If you’re looking to increase your bottom line without sacrificing the quality of your product, consider metal stamping. To create new components, stamping presses transform metal blanks into desired shapes through the use of a tool and die. With a variety of modifications, metal stamping can create numerous shapes for your product, giving you greater…