Reshoring is the process of bringing outsourced jobs back to their home countries. It has become an increasingly popular trend in recent years in an effort to strengthen the American economy. This shift in business strategy can offer a wide range of benefits to businesses, both large and small, from increased efficiency and improved customer…

Reshoring – All You Need to Know

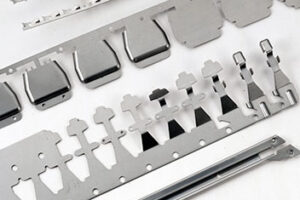

Over time, manufacturing industries shifted production from the United States to countries like China. Offshoring, the practice of moving a company’s manufacturing facilities overseas, began in the late 1970s. Many companies made the move to capitalize on lower labor costs and lenient environmental regulations in foreign countries, thus enabling them to generate higher profits for…

U.S. Production Costs Becoming Competitive With China

A new report has shown that over the past 10 years, manufacturing in the United States has started to become more competitive compared to many low-cost rivals- the most notable one being China. Today, U.S. factories are able to produce goods at cheaper prices than many of those produced in Eastern Europe. According to the…

The Problem with Outsourcing

One of the biggest conversations surrounding American manufacturing these days is reshoring; companies of all sizes are bringing business and jobs back to American soil. It’s welcome news for the industry. As some companies still make the decision to outsource—and as many of us focus on the reshoring trend—what many people are not talking about…

The Rebirth of Made In America

For many years, Made In America became synonymous with higher labor costs and declining quality. Company after company took their business overseas looking to boost profits. Without question, this mass exodus was devastating to the economy, as it stripped once proud towns and cities of jobs, factories, and pride. Thankfully, the trend of outsourcing is starting to…