Click To Open All manufacturing and molding processes require machine tooling, which is the process of building or producing various fixtures, jigs, and molds needed to create parts and products. Good tooling enables the creation of high-quality products, prolonging product longevity and guaranteeing proper functionality. Generally, the tooling process tends to vary from one application…

AIC’s Ultimate Guide to Roof Flashing

Flashing is a thin sheet of material that prevents water from entering cracks and other openings in a roof. Roofers apply the material under the shingles to repel water and redirect it to a location like the gutters. Flashing is vital to protect various roofing vulnerabilities, including where the roof meets the wall, edges, low…

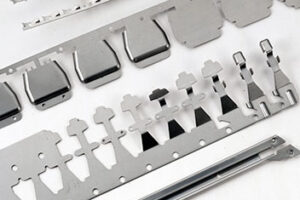

Top 3 Reasons to Choose American Industrial Company for Your Metal Stamping Needs

Click to Expand American Industrial Company is leading the way for metal stamping manufacturers with high-quality custom solutions for our clients throughout North America and in Europe. With a 25,000-square-foot facility just north of Chicago O’Hare airport, we specialize in turnkey packages that take your project from design to prototype to precise finished product. Since…

The Advantages of Cold Rolled Metal Stamping vs. Hot Rolled Metal Stamping

Depending on your application, you may be wondering whether hot rolled or cold rolled metal stamping is the best choice. Each provides advantages for different applications. However, the chemical composition of a material grade can differ depending on the manufacturing process. This blog will explore the differences between hot roll and cold rolled steel and…

Why Choose Metal Stamping for Electronic Components?

The electronics industry is constantly changing. New technological innovations come out rapidly, and that means that manufacturers need to stay on top of current trends and produce innovative new items quickly, accurately, and cost-effectively. An expansive range of electronics available on the market today contain components that were stamped (or could have been). Precision metal stamping…

The Metal Stamping Forecast for 2021

Because so many industries rely on metal stamping for their precision metal parts, metal stamping services remained in demand throughout 2020, despite the many changes and challenges the world experienced due to the COVID-19 pandemic. Efficient and cost-effective, metal stamping allows for accurate production with an automated process that reduces a company’s labor costs. You can…

The Importance of Metal Stamping for Power Tools and Construction

The construction and power tool industry is integral for many tasks around the globe from creating homes and commercial buildings to use in everyday life. Since power tools and construction equipment are often exposed to harsh building environments, such as extreme temperatures, impacts, vibrations, and more, the industry relies on high-quality stampings capable of withstanding…

Why You Should Avoid Scrap Generation and How to Do It

Many manufacturing operations and machine shops consider excess metal scrap as part of the cost of doing business. As a result, many manufacturers fail to implement planning and process improvements that can minimize the amount of scrap they generate during production. While scrap can be recycled to recoup some financial loss, minimizing scrap generation has…

The Optimal Metal Finishing For Your Industry Application

The optimal metal finishing chosen for an application can significantly influence the performance and success of a project. When selecting the finish for a part or product, it is important to keep in mind what best suits the specific use case. The following blog post provides an overview of the different finishes available, including their…

Why Choose Our Laser Cutting Services for Your Manufacturing Needs?

Laser cutting is one of the most commonly used processes in metal fabrication as it offers many advantages over traditional techniques. Laser cutting is a versatile and reliable process that creates precise, flawless parts while keeping lead times short. AIC provides high quality laser cutting services for sheet metal and other materials to meet our…