Laser cutting is one of the most commonly used processes in metal fabrication as it offers many advantages over traditional techniques. Laser cutting is a versatile and reliable process that creates precise, flawless parts while keeping lead times short. AIC provides high quality laser cutting services for sheet metal and other materials to meet our customers’ metal stamping and forming needs.

What is Laser Cutting?

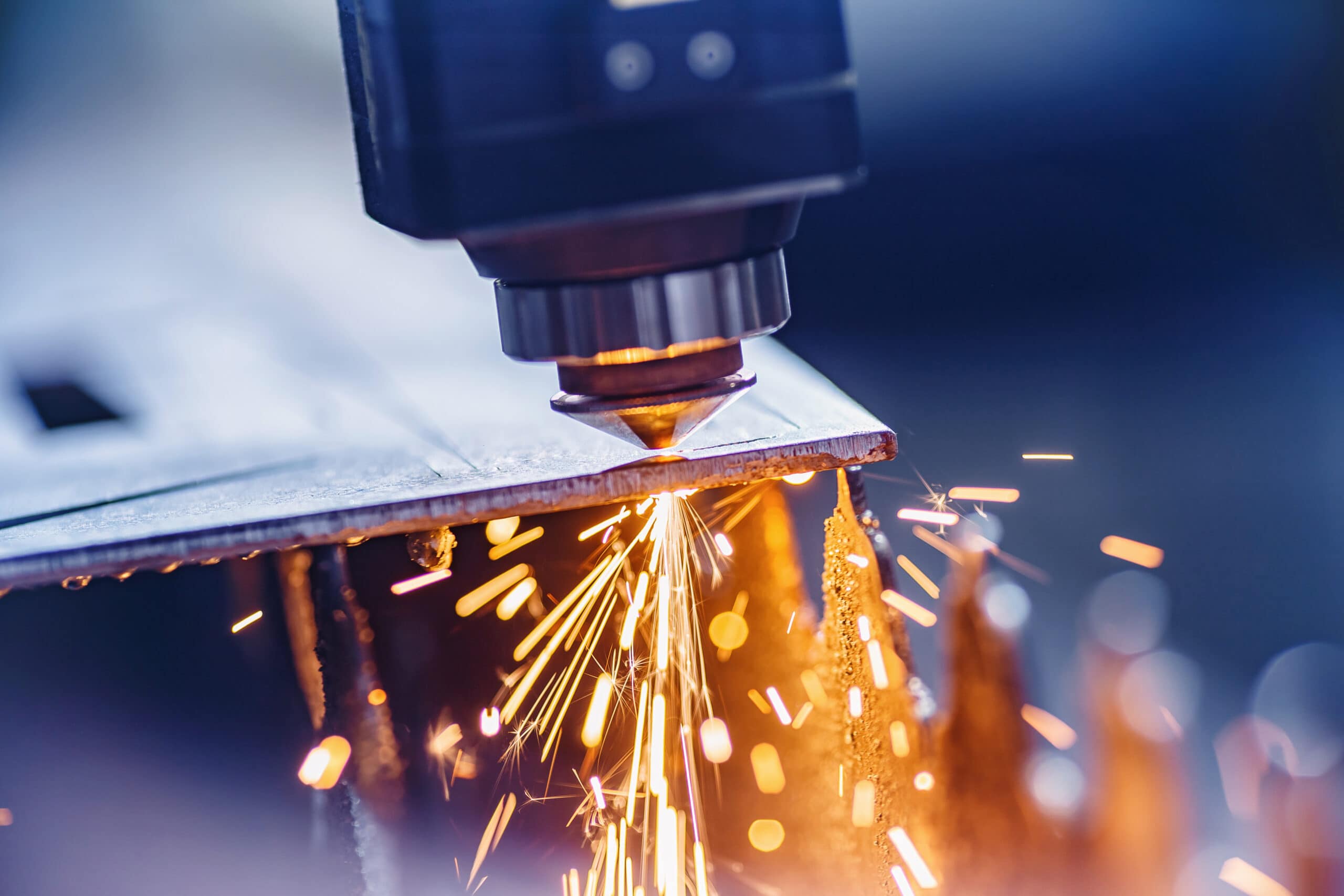

Laser cutting is a thermal-based procedure that utilizes a high-powered laser beam to direct heat and cut through metal with extremely tight tolerances using computer numerical control (CNC). As the guided laser moves across the surface, it vaporizes, melts, or burns material away and separates the workpiece from the excess sheet metal to create metal components and parts.

The focus of the laser allows for a smaller heat-affected area and less thermal warping than traditional methods, making it more accurate and efficient. This process also enables very high surface quality, so finishing processes are rarely needed.

Laser cutting can be performed on a variety of materials, including:

- Stainless steel

- Mild steel

- Aluminum

What are the benefits of Laser Cutting?

Laser cutting offers many benefits over traditional cutting methods, including:

- Laser cutting has tight tolerances of +/-0.1 mm, which allows for a high level of precision without the need for after-treatment.

- Laser cutting can perform separate cuts without exchanging tools, making it suitable for cutting different shapes and intricate designs within the same material thickness.

- Tight tolerances enable the production of highly uniform end pieces, which is extremely ideal for large volume orders.

- Cost-Effectiveness. Laser cutting significantly reduces the need for finishing processes to correct defects such as thermal warping and burrs. This reduces the need for additional tooling and processes that can slow down production and increase costs.

- Laser cutting is a non-contact process, reducing the risk for accidents and enhancing safety.

- Laser cutting is a much faster process when compared to traditional cutting methods, making it especially suitable for complex cuts.

Why should you choose American Industrial Company?

AIC has been in the metal stamping and forming industry for over thirty years. Our broad range of capabilities and highly skilled team can bring life to any project, from design through full-scale production.

To accommodate all laser cutting needs, AIC uses the VyTek FiberCAB 44 laser cutting system. This 3,000-watt laser is one of the most advanced machines of its kind and brings speed, efficiency, and precision to all metal cuts. Our VyTek FiberCAB 44 is accurate enough to cleanly remove stamped parts from the sheet metal with no need for secondary tooling processes like deburring.

Due to the versatility and power of our laser cutting machines, our services are applicable across diverse industries, including:

- Appliance

- Hardware

- Automotive

- Aerospace

- Construction

AIC’s preferred laser cutting method is the melt and blow method. With this method, a high-pressure gas jet is directed through a nozzle to blast small molten particles away from the workpiece. This method has lower power requirements than other forms of laser cutting and produces a fine kerf without thermal warping or burrs.

Contact American Industrial Company About our Laser Cutting Services

AIC specializes in providing high quality laser cutting services for our customers across a range of industries. Whether you are looking to make metal components that require intricate cuts, bolster production volume, or tighten tolerances, we believe that our precision laser cutting services can bring you real value at a great cost. To learn more about our services, please contact us today.