Ferrous & Non-Ferrous Metal Stampings

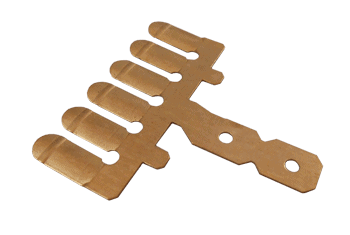

Metal stamping is a fabrication process that converts flat metal sheets into specific shapes and designs through bending, cutting, and shaping procedures using specialized machinery and dies. It is a highly versatile process that requires understanding the behavioral characteristics of the materials being cut and formed. Each metal type has distinct properties, and although many can undergo stamping, each falls into one of two categories: ferrous or non-ferrous.

Ferrous Metals

The main distinguishing factors of ferrous metals are their iron content and magnetic properties. Ferrous metals are strong and durable, commonly used in industrial and construction projects, but vulnerable to rust when exposed to moisture. When choosing a ferrous metal for stamping, consider properties such as ductility, elasticity, weldability, toughness, yield strength, and thermal expansion.

Commonly stamped ferrous metals include:

- Steel

- Carbon steel

- Alloy steel

- Wrought iron

- Cast iron

Non-Ferrous Metals

Non-ferrous metals do not contain iron in their composition, making them more corrosion- and rust-resistant than ferrous metals. They are also lightweight, soft, and malleable, making them suitable for applications where weight, rust, and exposure to moisture are concerns. For example, non-ferrous metals are used to make liquid-carrying pipes and rain gutters.

Commonly stamped non-ferrous metals include:

- Aluminum

- Brass

- Bronze

- Copper

- Silver

- Tin

- Zinc

Applications

The best material choice for your metal stamping application depends on the desired properties and requirements of the stamped part. Here are common applications of these popular metal types:

Ferrous Metals

- Stainless steel: This steel alloy is made by adding chromium to its composition, improving its strength and corrosion resistance for automotive, aerospace, and medical applications. Non-ferrous stainless steel is ideal for surgical equipment, cutlery, appliances, and piping fixtures.

- Carbon steel: Boasting superior strength and durability, carbon steel is excellent for constructing structural beams, pipelines, and auto parts.

- High Carbon Steel: This type of steel has higher amounts of carbon compared to stainless steel, enhancing its strength. It is commonly used to make tools like knives, axes, saws, and drills.

- Cast iron: Cast iron is brittle and wear-resistant. It is used to construct engines, machine tools, waterpipes, stoves, and utility hole covers.

- Wrought iron: Due to its rust and corrosion resistance, wrought iron is commonly used for railings, gates, and fences.

Non-Ferrous Metals

- Aluminum: This lightweight metal is a great choice in applications where weight is critical, such as making airplane parts. Aluminum is also easy to shape, so it’s used in applications that require malleable materials like making cookware, food cans, castings, and cars.

- Copper: Copper is highly malleable and ductile and a good conductor of electricity and heat, making it great for wires conductors, cartridge cases, and sheet roofing. When zinc is added to copper, it forms the alloy brass.

- Lead: Due to its low tensile strength and melting point, lead is used to make batteries. Other applications include making fuel storage and transportation systems and protective sheathing material for electrical power cables.

- Zinc: Zinc is commonly used to prevent the rusting of iron and steel by providing a protective coating around the metals through galvanization.

Advantages of Ferrous and Non-Ferrous Metals for Metal Stamping

The specific advantages of ferrous and non-ferrous metals vary depending on the metal or alloy composition type.

Here are some of their benefits in metal stamping:

Advantages of Ferrous Metals

Ferrous metals have a high tensile strength making them suitable for applications demanding durability and a high load-bearing capacity. They do not incur damage easily and provide reliable performance in their applications. Ferrous metals are good conductors of electricity and have magnetic properties, which is advantageous in mechanical and electrical applications. They are also easily recyclable, making them cost-efficient and better for the environment.

Advantages of Non-Ferrous Metals

Non-ferrous metals are lightweight and malleable, making them easier to handle and suitable for many applications. They also have high electrical conductivity, which is useful for electronic and wiring applications. Non-ferrous metals are also highly resistant to rust and corrosion due to their lack of iron content.

Precision Metal Stamping Services at American Industrial

Ferrous and non-ferrous metals are versatile, and their unique properties make them valuable materials in metal stamping. Both metal types have distinct characteristics, and it’s essential to understand their various properties to determine which metal suits best suits your application.

American Industrial offers precision all-metal stamping services for various automotive, electronics, tools, and medical equipment applications. Contact us today to discuss your project requirements or to request a quote.