Metals, collectively, provide a versatile and adaptable range of construction materials for countless applications. They are widely available in different compositions with various physical and chemical attributes. However, what makes metals unique is the ability to customize their properties by combining them with other metals to create alloys. Specific properties can be intentionally modified to make them fit for environments that would otherwise be unsuitable.

Each metal or alloy comes with its own unique set of benefits and limitations that lend themselves to different ideal uses. Selection of the most appropriate metal is, therefore, of utmost importance to achieve the best results for a particular metal stamping project.

In this article, we will look at typical metals used in the metal stamping industry, their most common applications, and their primary weaknesses.

CARBON STEEL

Carbon steel is the most common type of steel used today. The American Iron and Steel Institute (AISI) defines carbon steel as steel with a carbon content of up to 2.1% by weight. It may also contain traces of other elements such as chromium, cobalt, nickel, and titanium, among others.

One of the most desirable properties of low-to-medium carbon steel (0.05% to 0.6%) is its malleability and ductility. It can be easily bent, cut, twisted, and welded to create a wide range of shapes. This makes it ideal for auto parts, pipelines, structural beams, axels, and gears. High carbon steel (0.61% to 1.5%) is considerably stronger, and is commonly used for metal and woodcutting tools such as axes, drills, saws, and knives.

Low carbon steel, however, possesses a relatively low tensile strength, making it unsuitable for applications where the material will be subjected to high levels of stress. On the other hand, while the yield strength of high carbon steel is significantly higher, it is difficult to weld and susceptible to brittle failure.

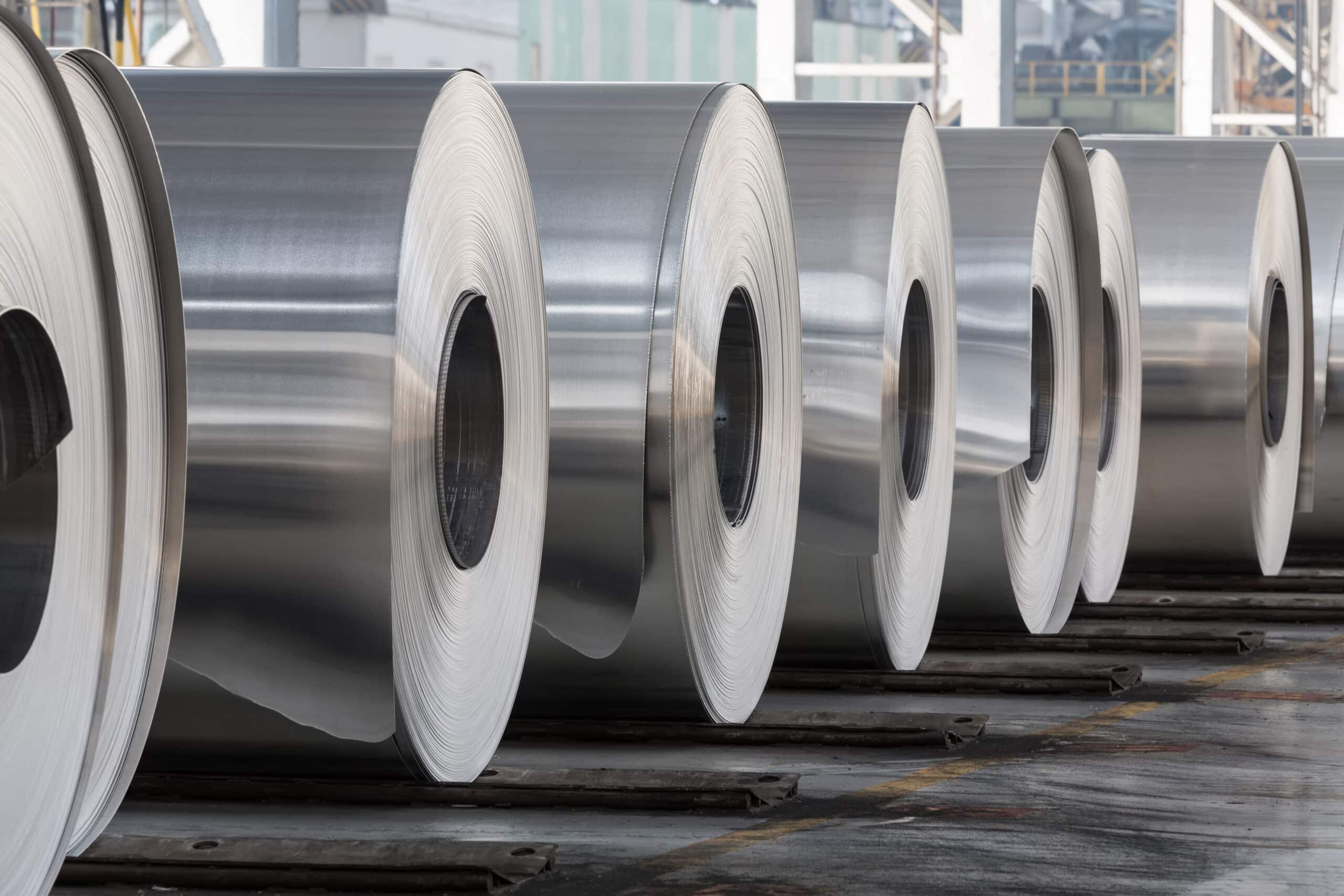

STAINLESS STEEL

Stainless steel is a carbon steel alloy with at least 10.5% of chromium by mass. Stainless steels are renowned for their superior corrosion resistance, which increases with increasing chromium content. This steel alloy is usually combined with other elements such as molybdenum, and nickel to further enhance corrosion resistance.

Due to its excellent balance of strength and corrosion resistance, stainless steel is used in numerous sectors, including the food and beverage, medical, automotive, and aerospace industries. It can be rolled into sheets, bars, and wires to be used in cookware, cutlery, surgical equipment, kitchen appliances, and sanitary piping fixtures.

One of the main disadvantages of stainless steel is its considerably higher cost when compared to carbon steel. This extra cost is usually due to the addition of alloying elements.

NON-FERROUS METALS

Non-ferrous metals are a subdivision of metal elements and alloys that do not contain iron. Examples of non-ferrous metals include titanium, aluminum, tin, lead, zinc, chromium, copper, and brass. Unlike ferrous metals, non-ferrous metals do not rust when exposed to atmospheric conditions.

Non-ferrous metals possess several desirable properties such as a light weight, electrical conductivity, non-magnetic properties, and corrosion resistance. Depending on the actual metal used, these metals can be used in a wide range of applications, including electrical circuits and wiring, aerospace components, jewelry, and automobile parts.

Although the price of non-ferrous metals varies according to the specific metal, they are generally more costly than ferrous metals. Also, even though their light weight can be advantageous in some situations, they are typically excluded from use in applications where strength or heft is required.

LEARN MORE

Understanding the advantages and disadvantages of various types of metals can help in predicting the overall quality and effectiveness of the material in a given environment, which can ultimately save time and money in your metal stamping application.

To learn more about how we can assist you in selecting the optimum material for your unique application, download our eBook, Key Strengths & Applications of Carbon Steel, Stainless Steel, and Non-ferrous Metals or contact us today.